lab report hardness test nails|rockwell hardness test lab report : inc Procedure for Brinell Hardness Test: 1. Verify using the test block that the machine is accurate. 2. Determine the proper load to apply to the sample: 3000 kg for steel and 1500 kg for aluminum. . The AMSCO 400 Series Small Steam Sterilizer (autoclave) provides efficient sterilization for .Tuttnauer provides laboratory autoclaves with advanced cycle programs and features designed .

{plog:ftitle_list}

The Flash vessel is located after the autoclave and prepares the slurry for further processing. The purpose of The Flash vessel is to . See more

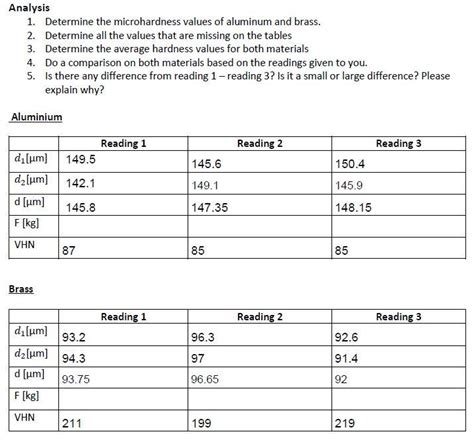

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material.The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

how to see what the percent glycolysis in a refractometer

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.Procedure for Brinell Hardness Test: 1. Verify using the test block that the machine is accurate. 2. Determine the proper load to apply to the sample: 3000 kg for steel and 1500 kg for aluminum. .Hardness is defined as resistance to plastic deformation from forces like scratches or indentation. The Rockwell hardness test uses different loads and indenters to penetrate materials and . The two standard property tests are the Rockwell Hardness Test and the Charpy Impact Toughness Test. As the name suggests, the Rockwell Hardness Test is a procedure .

Mainly, annealing will increase ductility while decreasing hardness. These changes increase the formability of the annealed metal and it more workable. This is consistent with our .

vickers hardness lab report

Any time we file our nails with a nail file or scratch a CD with our finger nails, hardness is involved. Hardness is used to measure a variety of resistances including: . The Rockwell hardness test is an indentation test that measures the deformation that occurs when the material is penetrated with a specific type of indenter, which indicates the .

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.

Procedure for Brinell Hardness Test: 1. Verify using the test block that the machine is accurate. 2. Determine the proper load to apply to the sample: 3000 kg for steel and 1500 kg for aluminum. 3. Set the amount of time for the test. In this lab we will use 12 seconds as our test time. 4.Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: • Scratch tests are the simplest form of hardness tests. In this test, various materials are rated on their ability to scratch one another. Mohs hardness test is of this type. This .

Hardness is defined as resistance to plastic deformation from forces like scratches or indentation. The Rockwell hardness test uses different loads and indenters to penetrate materials and determine the hardness value based on indentation depth.

The two standard property tests are the Rockwell Hardness Test and the Charpy Impact Toughness Test. As the name suggests, the Rockwell Hardness Test is a procedure that measures hardness, which is the resistance of a material to permanent damage after an external impact was applied. Mainly, annealing will increase ductility while decreasing hardness. These changes increase the formability of the annealed metal and it more workable. This is consistent with our data because of the two samples of 1018 Steel (hot rolled Any time we file our nails with a nail file or scratch a CD with our finger nails, hardness is involved. Hardness is used to measure a variety of resistances including: scratching, cutting, and indenting (Ref. 2).

The Rockwell hardness test is an indentation test that measures the deformation that occurs when the material is penetrated with a specific type of indenter, which indicates the hardness of the material.The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material.

how to tell if jade is real refractometer

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.Procedure for Brinell Hardness Test: 1. Verify using the test block that the machine is accurate. 2. Determine the proper load to apply to the sample: 3000 kg for steel and 1500 kg for aluminum. 3. Set the amount of time for the test. In this lab we will use 12 seconds as our test time. 4.Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: • Scratch tests are the simplest form of hardness tests. In this test, various materials are rated on their ability to scratch one another. Mohs hardness test is of this type. This .

Hardness is defined as resistance to plastic deformation from forces like scratches or indentation. The Rockwell hardness test uses different loads and indenters to penetrate materials and determine the hardness value based on indentation depth. The two standard property tests are the Rockwell Hardness Test and the Charpy Impact Toughness Test. As the name suggests, the Rockwell Hardness Test is a procedure that measures hardness, which is the resistance of a material to permanent damage after an external impact was applied.

vicker's hardness test

rockwell hardness test lab report

Mainly, annealing will increase ductility while decreasing hardness. These changes increase the formability of the annealed metal and it more workable. This is consistent with our data because of the two samples of 1018 Steel (hot rolled Any time we file our nails with a nail file or scratch a CD with our finger nails, hardness is involved. Hardness is used to measure a variety of resistances including: scratching, cutting, and indenting (Ref. 2).

how to tell when beer fermentation is complete conical refractometer

Instrument reprocessing requires a series of steps to assure that contaminated patient-care items (dental instruments, devices, and equipment) are safe for reuse. All procedures must be performed correctly and in the .

lab report hardness test nails|rockwell hardness test lab report